-

Precision Excellence with OEM and ZCCC Cutting Tools

In the realm of machining precision, OEM Cutting Tools and ZCCC Cutting Tools stand out as paragons of excellence. With a combined legacy of innovation and precision engineering, these tools redefine the standards of cutting-edge technology in the manufacturing industry.

OEM Cutting Tools, renowned for their Original Equipment Manufacturer prowess, deliver unparalleled performance across a spectrum of applications. Crafted with meticulous attention to detail, these tools embody reliability and efficiency. The OEM range encompasses a diverse array of cutting solutions, each designed to meet the exacting demands of modern industries. From milling to turning, OEM Cutting Tools are the epitome of precision, ensuring optimal results in every operation.

.webp)

Complementing this excellence is ZCCC Cutting Tools, a name synonymous with cutting-edge solutions. ZCCC’s commitment to innovation is evident in their extensive range of high-performance tools. The ZCCC line-up caters to the most demanding machining requirements, offering a perfect synergy of durability and precision. Professionals worldwide rely on ZCCC Cutting Tools for their ability to consistently deliver superior results, making them an indispensable choice for those seeking top-tier performance.

In a competitive market where precision is paramount, OEM and ZCCC Cutting Tools emerge as the dynamic duo for professionals seeking the best. The fusion of OEM’s industry-leading expertise with ZCCC’s cutting-edge technology results in a synergy that propels manufacturing capabilities to new heights.

Investing in OEM and ZCCC Cutting Tools isn’t just a choice; it’s a commitment to excellence. Elevate your machining processes with tools that embody precision, reliability, and innovation. Stay ahead in the manufacturing game – choose OEM and ZCCC Cutting Tools for a future where precision knows no bounds.

-

Precision Tools, OEM Excellence

In the world of manufacturing precision, OEM Cutting Tools stand out as the epitome of excellence. These cutting-edge tools are engineered to perfection, setting new standards in the industry. With a focus on quality, durability, and precision, OEM Cutting Tools are the go-to choice for professionals seeking optimal performance.

OEM, or Original Equipment Manufacturer, signifies a commitment to delivering tools that meet the highest industry standards. These cutting tools are designed to cater to a wide range of applications across various industries, including automotive, aerospace, and general manufacturing. The precision engineering of OEM Cutting Tools ensures efficiency and accuracy in every cut, contributing to enhanced productivity and cost-effectiveness.

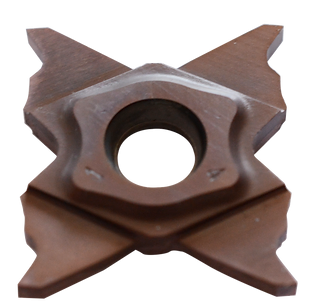

The durability of Grooving Inserts is unmatched, ensuring a longer lifespan and reduced downtime for operators. The tools are crafted from high-quality materials using advanced manufacturing processes, guaranteeing consistent performance even in the most demanding environments. This reliability makes OEM Cutting Tools an investment that pays off over time, providing a competitive edge to businesses that prioritize quality.

What sets OEM Cutting Tools apart is not just their performance but also the continuous innovation that goes into their development. The manufacturers consistently invest in research and development to stay ahead of technological advancements, incorporating the latest materials and design methodologies. This commitment to innovation ensures that users of OEM Cutting Tools benefit from state-of-the-art solutions that keep up with the evolving needs of the industry.

In conclusion, OEM Cutting Tools are more than just tools; they are a symbol of precision, quality, and reliability. Choosing OEM means choosing excellence in every cut. Upgrade your cutting experience today with OEM Cutting Tools and experience the difference that precision engineering makes in your manufacturing processes.

-

Precision Threads Await: Your Trusted Sandvik Distributor

In the world of machining excellence, precision is paramount, and so is the choice of your threading inserts. Elevate your machining game with the finest tools from a trusted Sandvik Distributor. Welcome to a realm where precision meets performance, and every thread tells a story of quality craftsmanship.

As your dedicated Sandvik Distributor, we bring you a curated selection of threading inserts designed to meet the exacting standards of modern manufacturing. Our commitment to excellence is reflected in every product we offer, ensuring that your machining processes are not just efficient but also yield results of unparalleled accuracy.

Why choose Sandvik threading inserts? The answer lies in a legacy of innovation and reliability. Sandvik, a name synonymous with cutting-edge technology, brings you inserts that redefine threading precision. From the toughest alloys to the most delicate materials, our inserts deliver consistent, high-quality threads, empowering your operations to reach new heights.

At JIN SHENG TRADE (DALIAN) CO.,LTD , we take pride in being your go-to Sandvik Distributor. Our team is dedicated to providing expert guidance, ensuring you find the perfect threading inserts for your specific needs. We understand the nuances of machining, and with Sandvik’s advanced solutions, we help you navigate the intricacies of your projects with ease.

Experience the difference that precision threading inserts can make. Trust in the heritage of Sandvik and the expertise of your reliable distributor. Elevate your machining capabilities, secure in the knowledge that every thread is a testament to the excellence that defines your work.

Choose JIN SHENG TRADE (DALIAN) CO.,LTD – where precision meets performance, and where Sandvik threading inserts are not just tools but an embodiment of machining perfection. Upgrade your threading game today!

-

Cutting Edge OEM Tools & Grooving Inserts

Are you in search of top-quality OEM cutting tools and grooving inserts? Look no further than A&Z Insulation, your trusted partner for precision and performance in the world of machining. Our 30 years of experience in the industry have made us a brand known for innovation and excellence.

When it comes to OEM cutting tools, A&Z Insulation is your one-stop destination. Our range of cutting tools is designed to meet the demands of the most challenging machining tasks. Whether you’re involved in metalworking, woodworking, or any other industrial application, our tools are built for precision and durability. We offer a wide variety of cutting tool solutions that cater to your specific needs.

Grooving inserts are essential for precision in machining operations. A&Z Insulation provides an extensive selection of grooving inserts that are renowned for their performance and reliability. Our inserts are designed to ensure accurate grooves and dependable results, making your machining processes more efficient and cost-effective.

At A&Z Insulation, we understand that the success of your operations depends on the quality of your tools. That’s why we are committed to delivering the best OEM cutting tools and grooving inserts. Our products are crafted with precision and undergo rigorous quality checks to ensure they meet industry standards and exceed your expectations.

Partner with A&Z Insulation for OEM cutting tools and grooving inserts, and experience the difference that precision engineering and quality materials can make in your machining operations. Trust us to provide the tools that empower your success.

Choose A&Z Insulation for cutting-edge tools that define excellence in the world of machining. We are dedicated to helping you achieve exceptional results, one cut at a time.

-

Your Trusted Sandvik Distributor for Deep Hole Drilling Tools

In the world of precision engineering, the choice of drilling tools is paramount. Deep hole drilling, in particular, demands high-quality tools for achieving precision and efficiency. As a trusted Sandvik distributor, JIN SHENG TRADE (DALIAN) CO.,LTD provides the solution for all your deep hole drilling tool needs. In this blog, we’ll delve into the significance of precision drilling and why JIN SHENG TRADE (DALIAN) CO.,LTD stands out as your top choice for Sandvik Deep Hole Drilling Tools.

The Importance of Quality Drilling Tools

Drilling is a fundamental process in various industries, including aerospace, automotive, and manufacturing. When it comes to deep hole drilling, quality tools are essential for the following reasons:

- Precision: High-quality tools ensure accurate and consistent hole drilling, vital for the production of intricate components.

- Efficiency: Quality drilling tools reduce machining time, leading to cost savings and improved productivity.

- Durability: Reliable tools are essential for long-lasting performance, minimizing downtime and tool replacement costs.

- Consistency: Precision drilling relies on the consistency provided by top-quality tools.

Why Choose JIN SHENG TRADE (DALIAN) CO.,LTD as Your Sandvik Distributor?

As a trusted Sandvik distributor, JIN SHENG TRADE (DALIAN) CO.,LTD offers a range of advantages that make them the ideal choice for your deep hole drilling tools:

- Sandvik Quality: Sandvik is a renowned name in the industry, known for its superior quality and precision. JIN SHENG TRADE (DALIAN) CO.,LTD ensures you have access to these top-quality products.

- Diverse Range: They provide a wide selection of Sandvik deep hole drilling tools suitable for various drilling applications.

- Custom Solutions: JIN SHENG TRADE (DALIAN) CO.,LTD offers tailored solutions to meet your specific drilling needs, ensuring the perfect fit for your projects.

- Competitive Pricing: Despite their top-notch quality, JIN SHENG TRADE (DALIAN) CO.,LTD’s Sandvik deep hole drilling tools are competitively priced, providing value for your investment.

- Exceptional Support: Their customer support team is dedicated to addressing inquiries, providing guidance, and ensuring your satisfaction.

Deep Hole Drilling Tools for Precision Engineering

Deep hole drilling is a specialized machining operation used for drilling holes with a high depth-to-diameter ratio. It’s often employed in applications where precision and consistency are critical, such as in the production of firearm barrels, medical implants, and hydraulic cylinders.

JIN SHENG TRADE (DALIAN) CO.,LTD: Your Precision Partner

When it comes to deep hole drilling tools, JIN SHENG TRADE (DALIAN) CO.,LTD is your precision partner. Their commitment to quality, precision, and customer satisfaction ensures you have the right tools for your deep hole drilling needs, contributing to your success in precision engineering projects. Don’t compromise on the quality of your drilling tools; choose JIN SHENG TRADE (DALIAN) CO.,LTD, your trusted Sandvik distributor, for top-notch products that elevate your deep hole drilling projects to new heights.

-

Unlocking Precision and Efficiency with OEM Cutting Tools – A Closer Look at ZCCC Cutting Tools

In the world of machining, precision is paramount. Whether you’re manufacturing complex aerospace components, automotive parts, or intricate medical devices, the quality of your cutting tools can make or break your operations. Original Equipment Manufacturer OEM cutting tools, such as those offered by ZCCC Cutting Tools, play a pivotal role in achieving superior results in machining. In this blog post, we delve into the significance of OEM cutting tools and explore what sets ZCCC apart in this competitive industry.

OEM Cutting Tools: A Foundation for Precision Machining OEM cutting tools are specifically designed and manufactured by the original equipment manufacturer, ensuring compatibility and optimal performance with the machinery for which they were intended. These tools are engineered to meet the highest standards of quality, durability, and precision, making them a preferred choice for various industries, including aerospace, automotive, and manufacturing.

Advantages of OEM Cutting Tools:

Compatibility: OEM cutting tools are designed to seamlessly integrate with the respective machining equipment. This compatibility ensures that the tools perform at their best, delivering consistent results.

Quality Assurance: OEMs prioritize quality control and adhere to strict manufacturing standards, resulting in tools that meet or exceed industry requirements. This commitment to quality ensures longer tool life and reduced downtime.

Precision Engineering: OEMs invest in research and development to create cutting-edge cutting tools that offer superior precision and performance. These tools are often at the forefront of technological advancements in the field.

Technical Support: Purchasing OEM cutting tools often comes with access to technical support and expertise from the manufacturer. This support can be invaluable in optimizing tool selection and machining processes.

ZCCC Cutting Tools: Elevating Precision Machining ZCCC Cutting Tools is a name that stands out in the world of OEM cutting tools. Here’s why they have garnered a reputation for excellence:

Diverse Product Range: ZCCC offers a comprehensive range of cutting tools designed for various applications, from milling and drilling to turning and threading. Their extensive product line ensures that customers can find the perfect tool for their specific needs.

Quality Commitment: ZCCC Cutting Tools places a strong emphasis on quality. They utilize advanced manufacturing processes, rigorous quality control, and precision engineering to produce tools that consistently meet industry standards.

Customization: ZCCC understands that not all machining needs are the same. They offer customization options, allowing customers to tailor cutting tools to their unique requirements, thereby optimizing efficiency and performance.

Technical Expertise: ZCCC Cutting Tools provides customers with technical support and guidance. Their team of experts assists in selecting the right tools, optimizing machining processes, and troubleshooting, ensuring that customers get the most out of their investments.

Innovation: ZCCC is committed to staying at the forefront of technology. They continually invest in research and development to introduce innovative cutting tool solutions that improve efficiency and reduce costs.

In conclusion, OEM cutting tools, such as those offered by ZCCC Cutting Tools, are the backbone of precision machining. They offer compatibility, quality, precision, and technical support that can significantly impact machining results. Choosing a reputable OEM supplier like ZCCC is a wise investment in achieving superior machining outcomes and staying competitive in the ever-evolving manufacturing landscape.

-

Top Engineering Tools and Arrangements

Inaccuracy designing, the tools and gear involved are significant in accomplishing exactness and proficiency. This article investigates fundamental arrangements in boring, turning, processing, and estimating, zeroing in on the Zccc Cutting Tools and suppliers that empower businesses to create significant parts and items.

Penetrating Arrangements: Accuracy Opening Making

Boring is a crucial cycle in assembling, and superior execution of boring apparatus is fundamental for making exact openings in different materials. Suppliers offer various bores to meet explicit machining prerequisites, including turn drills, step drills, and specialty bits.

CNC (Computer Numerical Control) is used to bore machines to accomplish accuracy and efficiency in penetrating tasks. Combined with cutting-edge bores, these machines guarantee reliable opening sizes and profundities.

Turning Arrangements and Parts

- Turning includes pivoting a workpiece, while a cutting device eliminates material to make tube-shaped parts. Cutting additions and device holders are urgent in this cycle, giving important accuracy and control. Suppliers offer various supplements and holders for multiple materials and applications.

- PC-controlled or CNC machines have changed turning activities with Big CNC Tools Supplier. These machines can execute complex turning errands with high accuracy, causing them to be significant in enterprises that require barrel-shaped parts with tight resistances.

Processing Arrangements: Adaptable Material Evacuation

Processing includes eliminating material from a workpiece’s surface utilizing turning cutters. Suppliers offer various processing cutters, from end plants and face factories to extraordinary profile cutters. These tools are fundamental for making many-sided shapes and accomplishing smooth completions.

CNC machining focuses have turned into the foundation of present-day processing activities. These profoundly mechanized machines can perform numerous errands, including processing, penetrating, and tapping, with uncommon precision with Sandvik Distributor.

Estimating Arrangements: Guaranteeing Accuracy

Exact estimations are basic in accuracy designing. Suppliers give accuracy estimation tools, including micrometers, calipers, and coordinate measuring machines (CMMs). These tools guarantee that parts meet precise details.

Notwithstanding actual estimation tools, quality control programming is utilized to investigate and oversee estimation information. This product helps with quality affirmation by distinguishing deviations and empowering speedy changes in machining processes.

Conclusion

A mix of cutting-edge tools and dependable suppliers drive accurate design. Whether boring, turning, processing, or estimating, the right tools and hardware are fundamental for accomplishing precision and effectiveness in assembling processes. Suppliers assume a significant part in giving admittance to these tools, guaranteeing that businesses can deliver top-notch parts and items that fulfill severe guidelines. In a consistently developing scene, remaining refreshed with the most recent headways in tools and innovation is critical to keeping an upper hand in accuracy designing.

-

CZ Cutting Devices: Your Chief CNC Instruments Provider and Sandvik Merchant

In the steadily developing universe of assembling and machining, approaching great cutting apparatuses is fundamental for accomplishing accuracy, proficiency, and efficiency. ZCCC Removing Devices remains a main CNC instruments provider and approved wholesaler of Sandvik items, offering an extensive scope of state of the art answers to meet the different requirements of the business.

- A Tradition of Greatness

With a set of experiences tracing back to [year of establishment], Zccc Cutting Tools have secured itself as a confided-in accomplice for organizations needing cutting apparatuses and machining arrangements. Throughout the long term, we have reliably shown a pledge to greatness, development, and consumer loyalty. Our broad experience and industry mastery have permitted us to comprehend the interesting difficulties faced by producers and to fit our contributions to successfully address these difficulties.

- Complete Item Portfolio

CZ Cutting Devices invests wholeheartedly in offering a broad item portfolio that takes care of different machining applications and enterprises. As an approved Sandvik Distributor, admittance is given to Sandvik’s a-list cutting instruments, which are famous for their accuracy, solidness, and execution.

- Master Direction and Backing

Our group of experienced experts comprehends the mind-boggling subtleties of machining processes and can offer master direction in choosing the most reasonable apparatuses for your particular necessities. We are focused on cultivating organizations with our clients, guaranteeing that they get the help and counsel expected to augment the advantages of our items.

Big CNC Tools Supplier remains a chief by supplying ZCCC Cutting Devices and approved Sandvik merchant, offering an extensive scope of top-notch cutting apparatuses and machining arrangements. With a tradition of greatness, a pledge to quality, master direction, and a commitment to development, we are your believed accomplice in accomplishing accuracy, effectiveness, and efficiency in your machining tasks. Reach us today to find out how ZCCC Cutting Apparatuses can raise your machining processes and add to your prosperity.

-

Reliable Partner as a Big CNC Tools Supplier: Exploring Deep Hole Drilling Tools

In the realm of CNC machining, the role of a dependable and resourceful supplier cannot be overstated. When it comes to sourcing cutting-edge tools and equipment, a big CNC tools supplier plays a crucial role in supporting manufacturing operations. Among the array of tools they provide, deep hole drilling tools stand out as essential components for achieving precision and efficiency in various industries.

Collaborating with a reputable big CNC tools supplier offers several advantages to manufacturing businesses. These suppliers often have access to an extensive range of cutting tools, ensuring that manufacturers can find the perfect tool for their specific needs. From end mills to inserts, they cater to diverse machining requirements. What distinguishes a reliable supplier is not only the product variety but also their commitment to quality, providing tools that adhere to the highest standards.

Deep hole drilling tools are a prime example of the specialized equipment that a big CNC tools supplier can offer. Deep hole drilling is a machining process that involves creating holes with a high depth-to-diameter ratio. These holes are typically used in industries such as aerospace, automotive, and oil and gas for applications ranging from cooling passages to oil wells. Deep hole drilling tools demand precision, rigidity, and specialized geometries to ensure accurate hole creation, efficient chip evacuation, and prolonged tool life.

A dependable supplier provides an array of deep hole drilling tools, including gun drills, BTA drills, and ejector drills, each designed for specific deep drilling applications. These tools incorporate advanced features such as coolant-through capabilities to enhance chip evacuation, specialized coatings for extended tool life, and innovative geometries for improved cutting performance. By partnering with a big CNC tools supplier, manufacturers gain access to these cutting-edge tools that are vital for their complex machining tasks.

Furthermore, a big CNC tools supplier often offers technical expertise and support to assist manufacturers in selecting the right tools and optimizing machining processes. This partnership goes beyond providing tools; it involves collaboration aimed at improving productivity and ensuring the success of machining operations.

In conclusion, choosing a reputable big CNC tools supplier is a strategic decision that can greatly impact manufacturing efficiency and precision. With their comprehensive range of cutting tools and specialized offerings like deep hole drilling tools, these suppliers become indispensable partners in the journey towards successful and accurate CNC machining operations. Whether it’s for intricate aerospace components or critical oil well applications, deep hole drilling tools sourced from a reliable supplier can make all the difference in achieving impeccable results.

-

Unveiling the Benefits of Grooving Inserts from a Leading Big CNC Tools Supplier

In the dynamic world of modern manufacturing, precision and versatility are paramount. One key player in this realm is the big CNC tools supplier, offering a diverse array of cutting-edge solutions to meet the demands of various machining applications. Among these offerings, grooving inserts stand out as indispensable tools that enable manufacturers to achieve intricate cuts, optimize efficiency, and elevate their machining processes to new heights.

Grooving inserts, often referred to as grooving cutters or parting-off tools, are specialized components designed for creating grooves, slots, and recesses in workpieces during CNC machining. These inserts are essential for a wide range of applications, from creating threads on cylindrical components to forming undercuts and chamfers. Their precision and versatility make them indispensable for manufacturers across industries such as aerospace, automotive, medical, and more.

One of the primary advantages of utilizing grooving inserts is the exceptional precision they offer. With tight tolerances and consistent cutting depths, these inserts ensure uniformity and accuracy in grooving operations. This level of precision is crucial for industries where even the slightest deviations can lead to compromised product quality and functionality.

Big CNC Tools Supplier Moreover, grooving inserts contribute to enhanced efficiency and reduced cycle times. The advanced geometries and coatings found in modern grooving inserts allow for higher cutting speeds and improved chip evacuation, minimizing downtime and maximizing productivity. Manufacturers can achieve faster material removal rates while maintaining the desired surface finish, resulting in streamlined operations and cost savings.

When it comes to complex geometries and hard-to-reach areas, grooving inserts shine. They enable manufacturers to create intricate grooves and profiles that would be challenging or impossible with traditional cutting tools. This capability is particularly valuable for industries that require intricate designs and custom components.

For manufacturers seeking a reliable source of grooving inserts and other CNC tools, partnering with a leading big CNC tools supplier is essential. These suppliers not only offer an extensive range of grooving inserts to cater to various needs but also provide valuable technical support and expertise. They understand the nuances of machining applications and can recommend the most suitable grooving inserts based on factors such as material type, cutting conditions, and desired outcomes.

In conclusion, grooving inserts play a pivotal role in modern CNC machining, enabling manufacturers to achieve precision, efficiency, and versatility in their operations. As part of the product lineup offered by a prominent big CNC tools supplier, grooving inserts empower manufacturers across industries to unlock new possibilities in their machining endeavors. With their ability to create intricate cuts, streamline processes, and elevate overall product quality, grooving inserts are an essential tool for any forward-thinking manufacturer looking to stay competitive in today’s fast-paced manufacturing landscape.

Totime Tools Co., Ltd

.webp)